By TYLER ELLYSON

UNK Communications

HASTINGS – When Rakesh Srivastava sees an opportunity to help others, he’s going to take action.

The University of Nebraska at Kearney graduate has proven that time and again throughout his career, so it’s no surprise that he’s stepping up to support the state during the ongoing coronavirus pandemic.

“Right now our community needs protection from this virus and the pandemic we’re in. So why not change direction and make something that can be used in this fight?” said Srivastava, who earned a bachelor’s degree in telecommunications management from UNK in 2002 and a master’s degree in instructional technology with an emphasis in assistive technology in 2006.

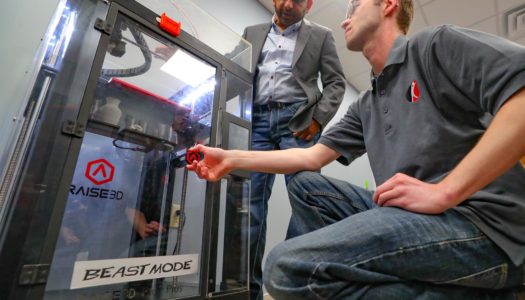

At his Shabri manufacturing facility in Hastings, Srivastava and three employees are using 3D-printing technology to produce the personal protective equipment that’s currently in short supply across the country.

“We don’t have many resources in our local area to produce some of these items, and the demand is going to increase every day,” Srivastava said.

Srivastava launched Shabri in February 2019 as an affiliate company of Innovative Prosthetics and Orthotics, which he started in 2006 and has since expanded to include clinics in Hastings, Grand Island, Omaha and his home country of India that provide comprehensive prosthetic, orthotic and durable medical equipment services.

Typically, Shabri manufactures custom-made prosthetic devices for patients while also fulfilling orders for customers, including those in the agricultural and brewing industries, that can utilize 3D printing instead of casting to have parts made faster and cheaper.

As the coronavirus outbreak worsened in the U.S., Srivastava shifted the facility’s focus about a month ago to producing 3D-printed face masks and shields.

The products, which are reusable, serve a diverse clientele – from individuals looking for added protection when they’re out in public to retail and service industry employees who interact with customers on a day-to-day basis.

“Anybody who is in contact with another individual, that’s where this face mask and face shield can be used,” Srivastava said.

Of course, health care workers and emergency responders are a top priority.

Srivastava recently donated 10 face shields to Mary Lanning Healthcare in Hastings and he’s in the process of donating another 30. He also plans to supply the local fire department with five face masks.

He’s coordinating with several agencies and state officials to identify additional needs in Nebraska.

“We are working day and night to produce these face masks and shields so we have resources available at the local level and our needs are met,” said Srivastava, who estimates his company can make 10,000 face masks and shields in three to four weeks if the demand is there.

Although the 3D-printed face masks don’t meet U.S. Food and Drug Administration manufacturing criteria, they are produced using an antimicrobial polymer and feature a filtration system that’s more effective than an N95 mask, according to Srivastava, whose company is also making medical-grade cloth masks. He said the 3D-printed masks could be used by health care workers if FDA-approved equipment isn’t available.

“We have to have different options at this time to protect ourselves,” Srivastava said.

Srivastava, a prosthetics user who lost his left leg in a childhood accident, earned a degree from the National Institute of Rehabilitation Training and Research in India before starting his career at the Akshay Pratishthan Rehabilitation Center in New Delhi. He moved to the U.S. in 1997 and is certified by the American Board for Certification in Orthotics, Prosthetics and Pedorthics.

A 2018 UNK Alumni Association Distinguished Alumni Award recipient, Srivastava served as associate director of telecommunications at UNK from 2005-08. He’s currently an adjunct faculty member in the University of Nebraska at Omaha’s Division of Biomechanics and Research Development and is part of the Cyborg Beast research team that developed an affordable and innovative prosthetic hand utilizing 3D printing.